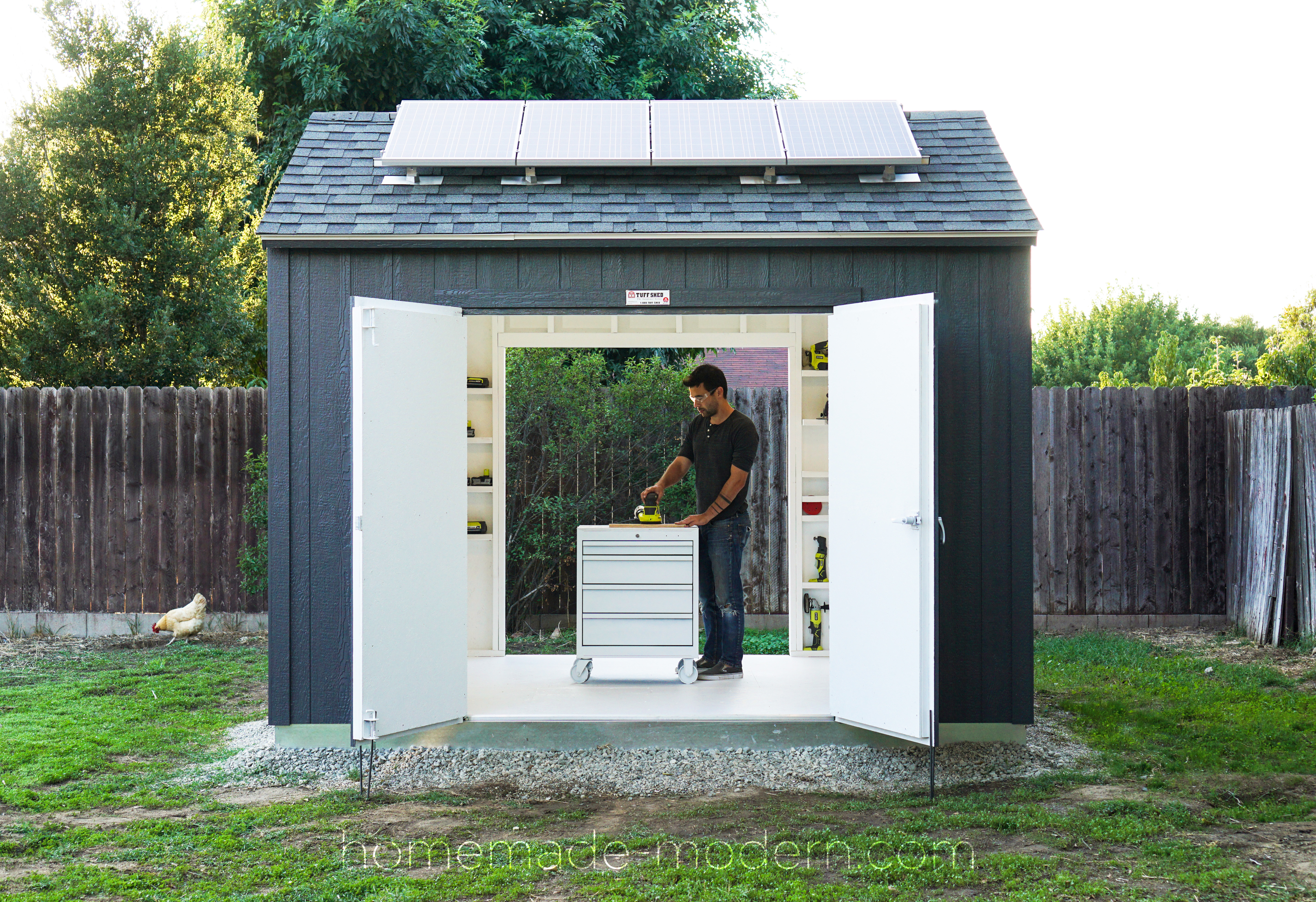

For my largest project to date I will show you how I built an off-the-grid solar powered workshop using products and materials from Home Depot. I started with a pre-fabricated shed from Tuffshed and added photovoltaic panels and a battery system that would allow me to run power tools as well as lawn and garden tools off of renewable energy. I got my solar panels in a kit that I bought from Home Depot. I used four 6-volt batteries to create a storage system and I am able to power both corded and cordless tools from them. The total cost of this project was $7500 and took about 20 hours to build.

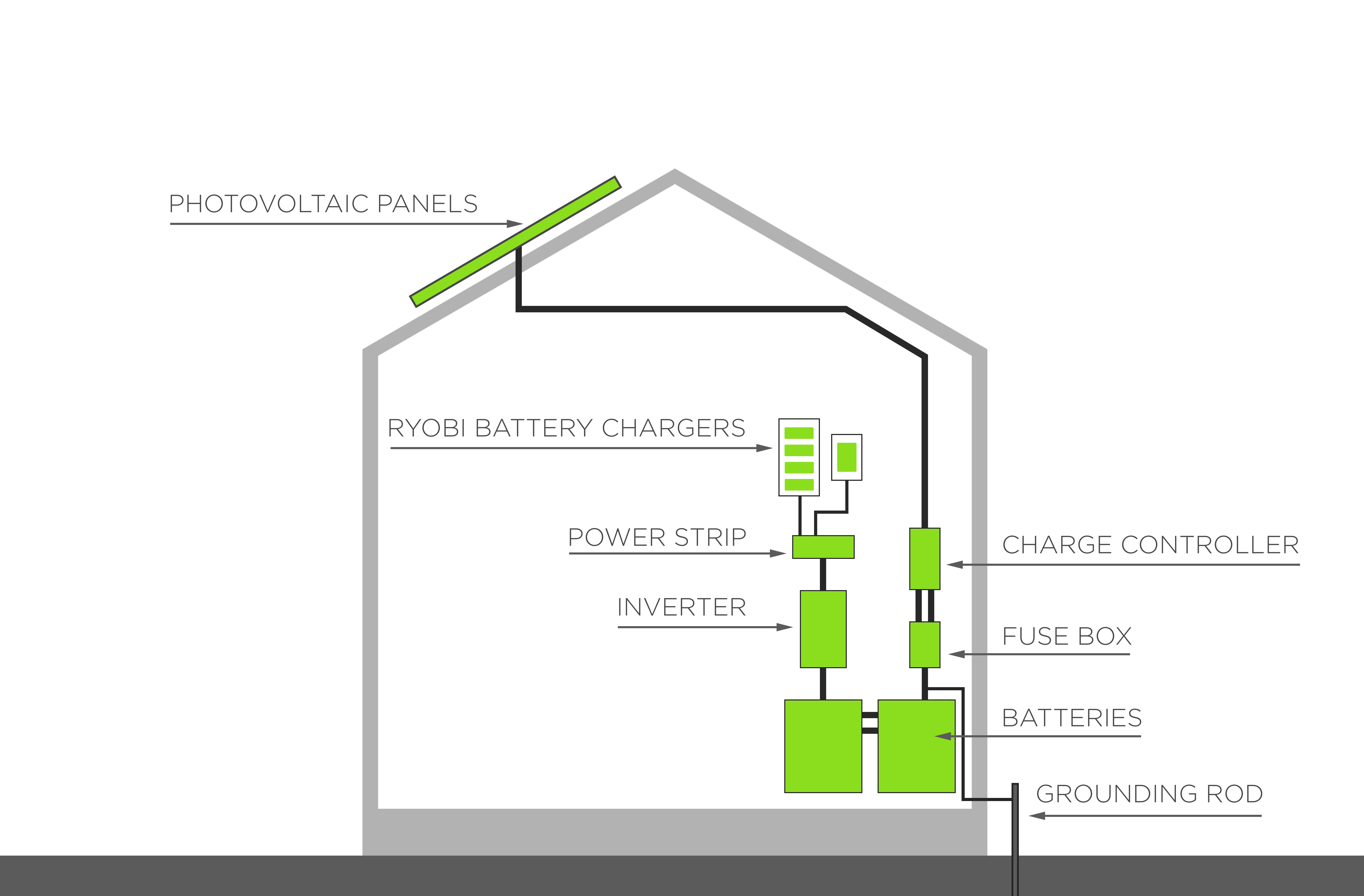

Solar Electric System Overview

Most of the components for this system came from this kit from Home Depot. This solar kit came with an inverter, charge controller, cables and four 100-watt photovoltaic panels. I have been able to power the drill press, band saw, the lights, and charge my RYOBI batteries all at the same time. I have only completed one project in this new shop so far but was able to work for 8 hours without seeing any drop in power. It seems to take about two moderately sunny days to fully charge the battery bank. 400 watts of solar is not that much but since the majority of the tools we use are battery powered we have a substantial buffer between energy usage and energy generation. If we were building for 12 hours every day we would need to add more panels but since we are typically building just 3-4 days a week this system is perfect. It’s easy to oversize a system but then you are paying for infrastructure that you are rarely using. I am really happy to replace gas powered lawn mowers and outdoor tools with battery powered electric tools that are being charged by the sun. Not only is it more convenient and less messy, it is also good for the environment. Two stroke engines like the ones in lawnmowers and leaf blowers produce a lot of emissions despite their relatively small size.

The electricity is generated by four 100 Watt photovoltaic panels.

The charge controller makes sure that the batteries are being charged in an optimal manner and are in between the photovoltaic panels and the batteries.

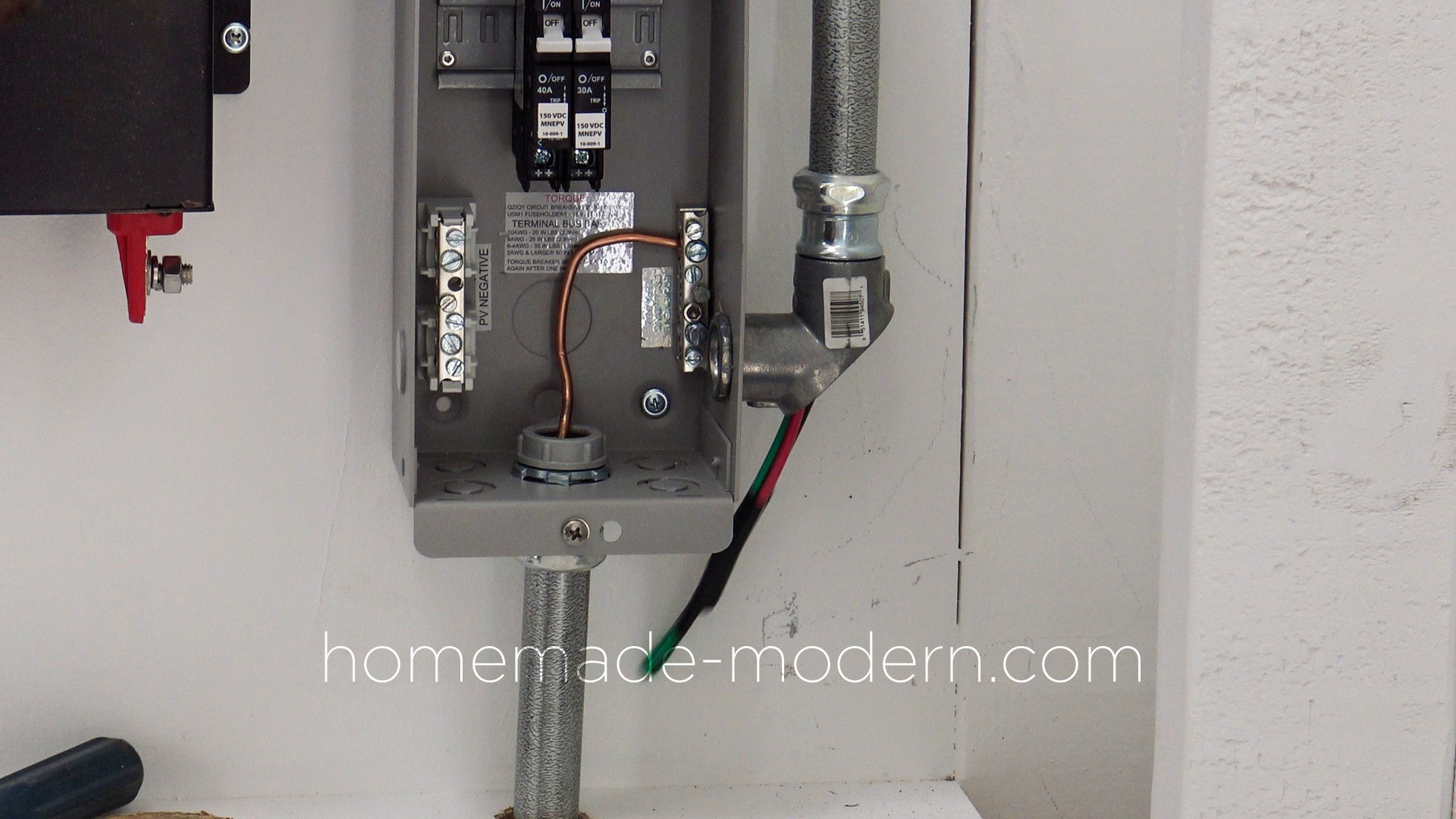

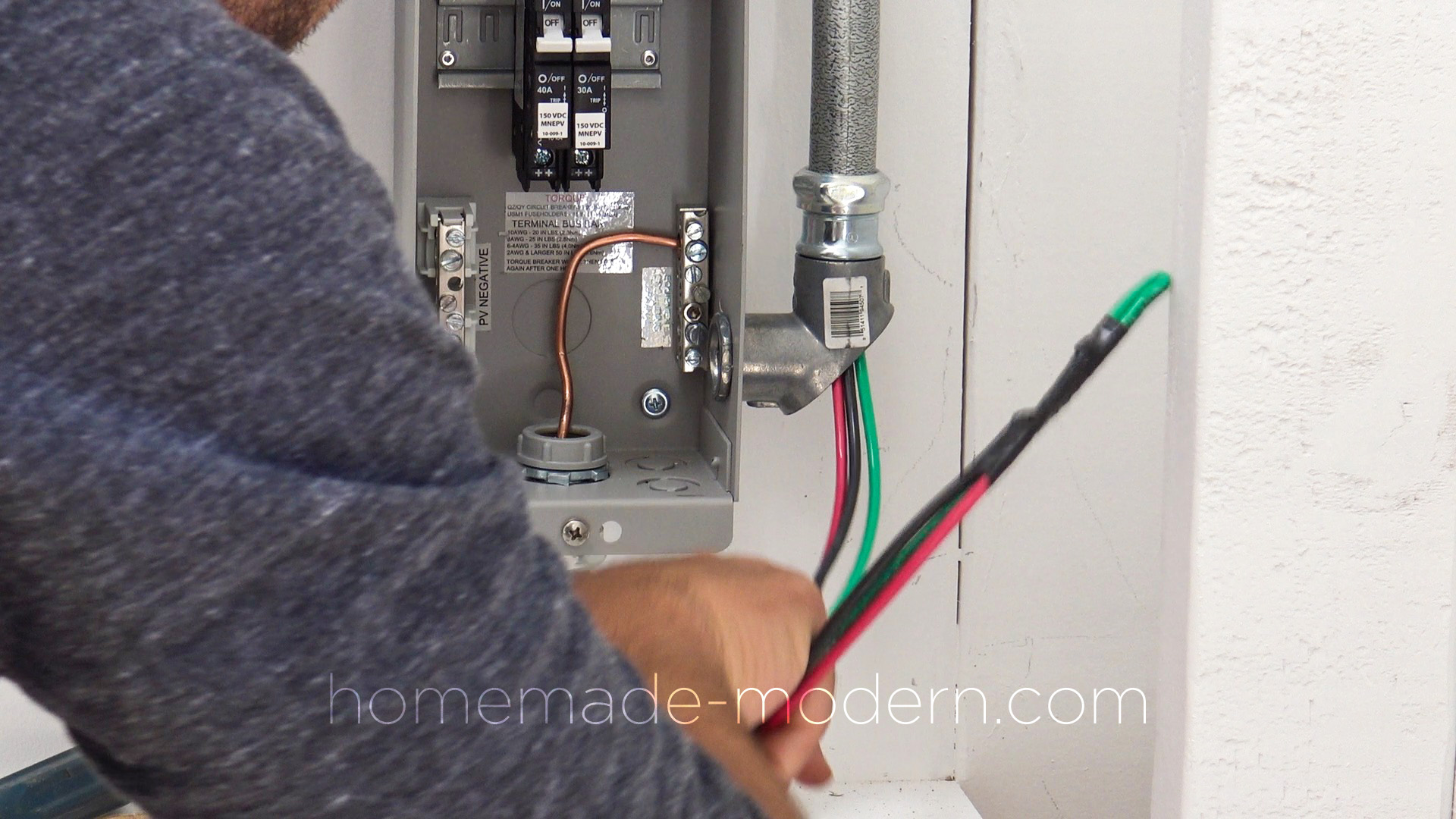

We added a fuse box to provide an additional layer of safety.

The energy is stored in four 6-volt sealed batteries.

The grounding rod is another safety measure that provides a path to discharge electrical surges.

The batteries provide direct current or DC whereas most corded tools and house hold appliances require alternating current or AC. The inverter converts DC to AC has two standard household plugs.

We are going to need more than the two plugs on the inverter so I plugged a power strip into the inverter to provide more plugs.

My power tools use 18 volt batteries that can be charged 6 at a time in my super charge. The lawnmower and other lawn and garden tools use 40-volt batteries that are charged one at a time.

INSTRUCTIONS:

After checking local building codes, I selected a location in the yard and used a tamper to pack down the soil. I then spread 3 inches of sand and then packed that sand down. I added 3 inches of gravel over the sand and packed that as well. I used a straight edge and a level to make sure that this compacted gravel foundation was relatively flat. I used 50lbs bags of Quikrete sand and gravel.

I ordered the Tuff Shed online. They have a great website that lets you customize the shed you want. I selected a 10 foot by 12 foot shed from Tuff Shed. The shed arrived in panels on a flat bed truck and their crew of two were able to assemble the entire thing in just 3-4 hours. They did a great job and made sure to touch up all the paint and clean up after construction. The foreman went over a detailed checklist with me to make sure I was 100% satisfied and got all the features I ordered. I picked a monochromatic grey shed with 2 sets of double doors, skylights, and 1 sliding window so that I could have plenty of light and air.

Here are the specs for the shed that I ordered:

| Part | Details |

|---|---|

| Base Building | TR-800 10ft. wide x 12ft. long |

| Roof | Upgraded Owens Corning Dimensional Shingles |

| Roof Color | Estate Gray Dimensional |

| Siding Color | Knight's Armor |

| Trim Color | Knight's Armor |

| Door Color | Knight's Armor |

| Options | 1 White Drip Edge, 1 6/12 Roof Pitch Upgrade (Sundance Ranches), 1 Horizontal Sliding Window (3 x 2), 2 Double Door Upgrade (6ft Wide x 6ft-7in Tall), 1 Additional Single Shed Door (4ft Wide x 6ft-7in Tall), 120 SQ FT Radiant Barrier Roof Decking, 2 Sky Light*** (2 x 2) |

I wanted an all white interior but all the exposed studs create a lot of corners and edges that would have taken a long time to paint buy hand. I bought a Wagner Paint Sprayer. This was my first time using one and it worked great! We were able to paint the entire shed in just about 2 hours. We used BEHR exterior paint in Ultra Pure White with a flat finish to paint the floors.

We used ¾” plywood to make a wall panel for hanging the electrical components on. We used plywood and 2x4s to make an enclosure for the batteries.

Jason Andrade from www.westcoastsustainables.com came by to help with the solar and electrical work. Jason added a fuse box to the system and we installed the charge controller, fuse box and inverter onto the plywood panel just above the battery enclosure.

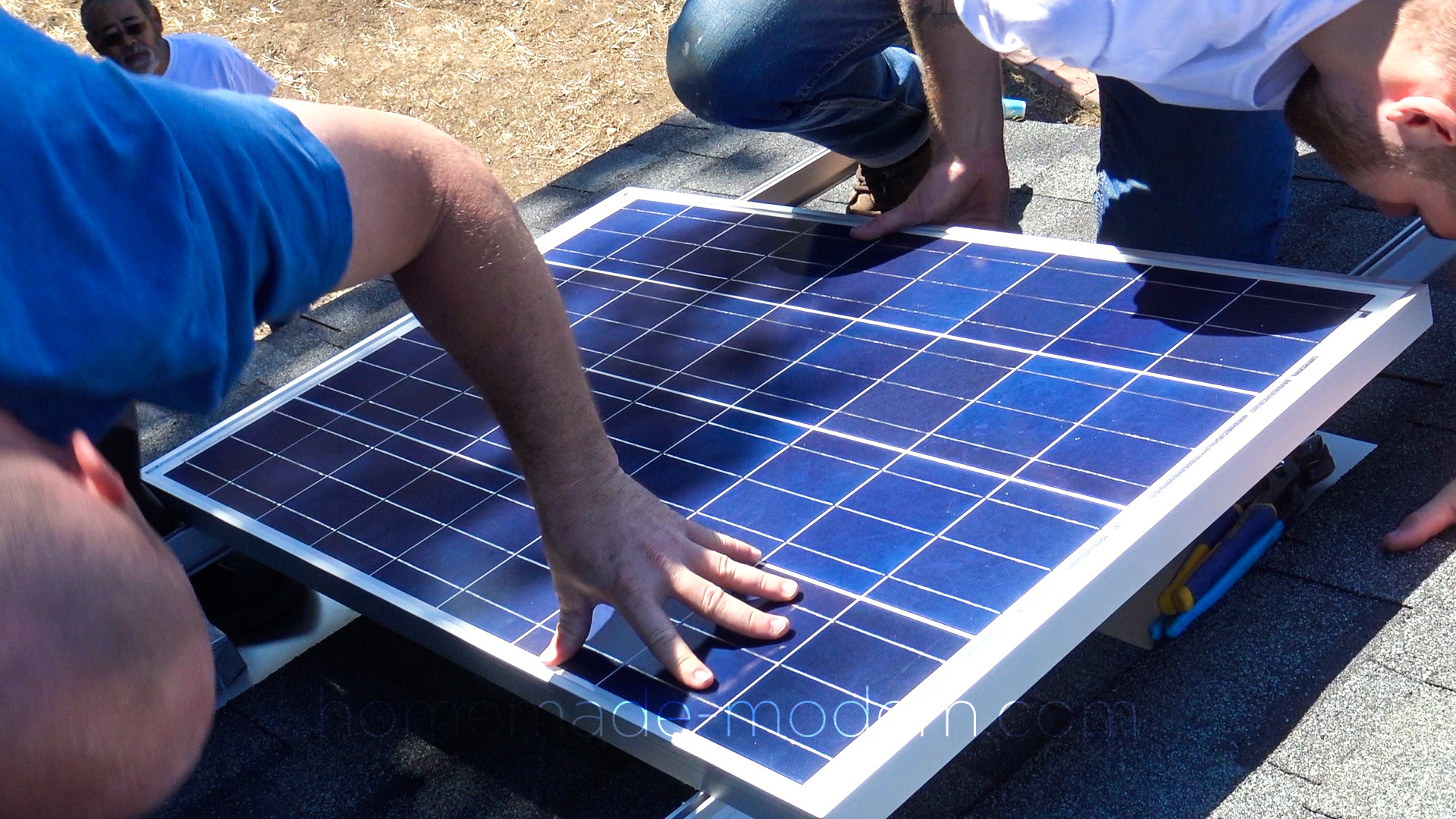

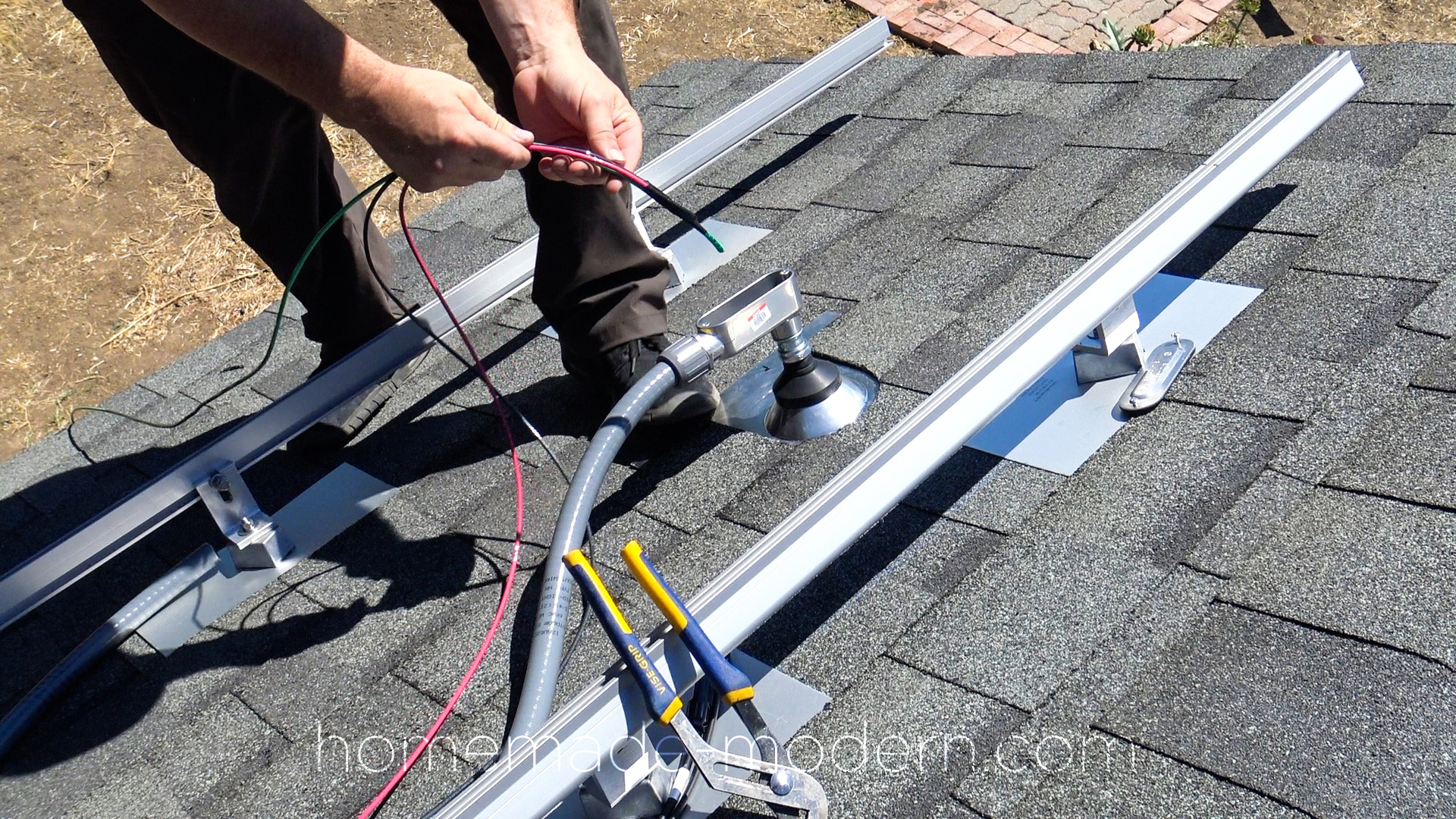

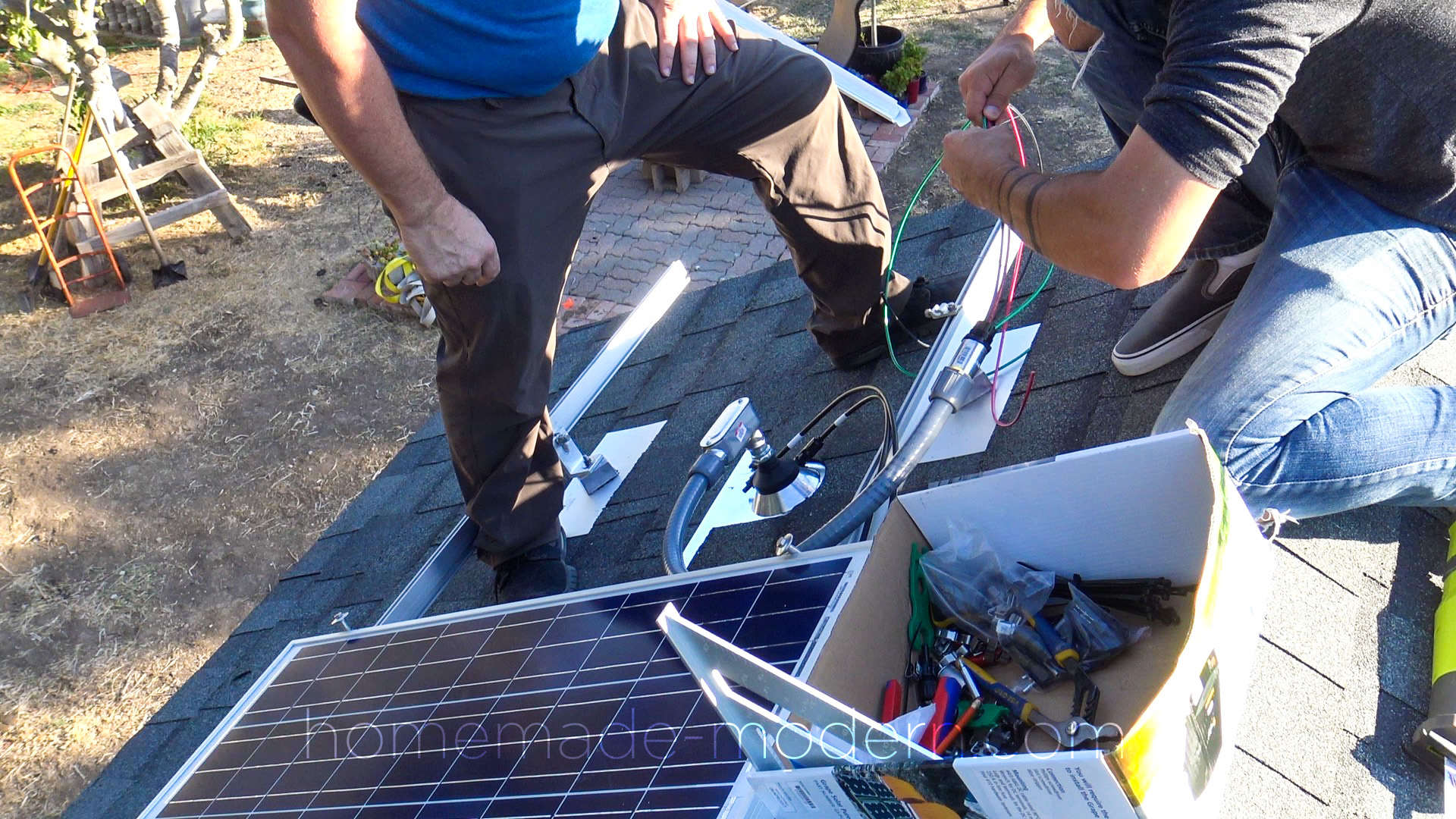

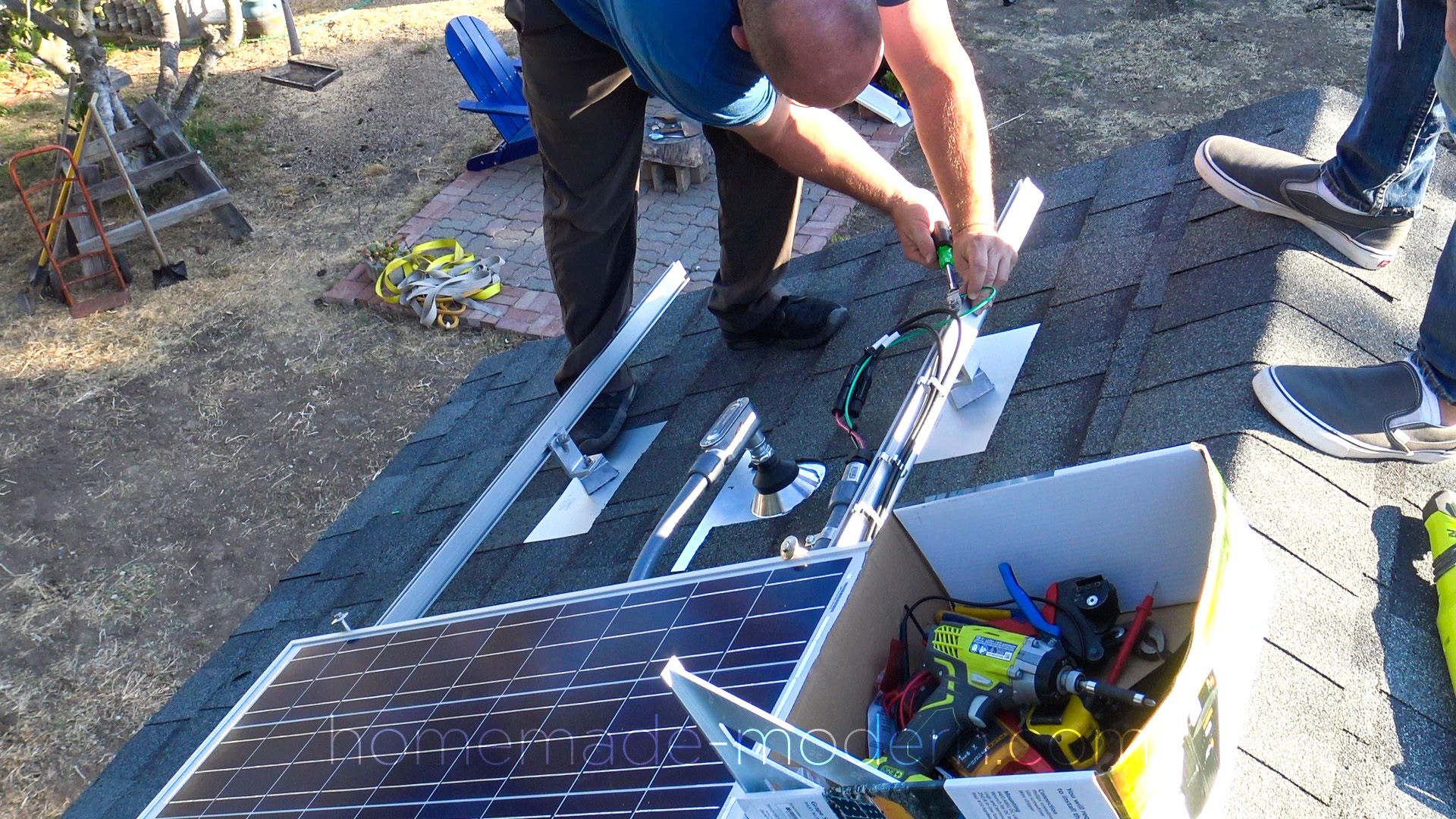

The key to installing solar panels is connecting them securely to the roof without creating leaks. We slid these pieces of flashing that also have mounting points for the rails under the shingles and then pre drilled holes for specialty lag screws through the roof and into the rafters below. We squirted in some sealant and then drove the lag screws through the flashing and into the rafters. These lag screws have bolt threads on the other end and we needed an extension on the driver to clear these threads. We then bolted speciality L-brackets onto these mounting points and then added the rails onto the brackets.

We wanted to place the hole for the cables to go through the roof directly under the center of one of the panels. We placed the flashing and then drilled a pilot hole from the top down. We used a hole saw to drill a larger hole from the bottom up.

We cut and bent ¾” conduit to make a path for the cables from the PV panels to the charge controller.

We added a conduit body right over where the conduit comes through the roof. We checked to make sure that this body wouldn't bump into the PV panels.

We drove a grounding rod into the ground and then drilled a hole through the wall of the shed for the jacketed grounding wire. We then connected the wire to the rod.

We drilled holes in the battery enclosure so that we could connect the various electrical components.

We connected the grounding wire to the fuse box.

We then connected all of the different components.

The trick to installing the panels is in keeping the wires secure and tucked up underneath the panels. If the wires drag along the roof the rough asphalt shingles can slowly erode them and cause failure. We installed the panels to the racks using these special bolts that look like mini UFOs. They slide into the tracks and clamp onto the frames of the PV panels.

I used a reciprocating saw to trim the rails and then pushed in these end caps so that spiders and dirt can’t get inside the hollow railings.

We tested out the system by running a band saw and a drill press at the same time. It worked great!

The batteries are sealed and require virtually no maintenance so we closed them up with just a few open slots for ventilation. We don’t want anyone accidently touching the cable connection.

We screwed some pieces of 2x4 between the rafters and used them to mount the pendant lights we got from Home Depot. We wired the lights to a 2nd power strip that we use as an on/off switch.

I cut up some plastic rain gutters and connected the pieces with couplings to make a light cove that I screwed to the top of the walls. I drilled holes through the studs so I could run wires to the power strip and then dropped in some LED lights.

I cut pieces of this Gladiator GearWall system with my compound miter saw. It’s a really cool looking system that is super strong and has lots of storage accessories. I screwed the panels to the studs and inserted the shelves and hooks into the slots.

I glued and screwed pieces of ¾” plywood together to make a countertop two layers of plywood thick that runs the width of the workshop. I then ripped some strips of plywood on the table saw and glued and screwed those to the front edge of the countertop. I used my belt sander to remove the excess glue and then painted it with four coats of Rustoleum oil based enamel using the smoothest finishing roller I could find at Home Depot. The surface came out great!

I got two of these Husky rolling tool chests from Home Depot and painted them white. I am going to use them not just for storing tools but to create a center work island that can roll under the countertop when not in use.

I cut pieces of 2x4 and 2x6 to make shelves and supports for the countertop. I sanded them with an orbital sander before painting them white and screwing them in between the studs. I screwed a 2x4 to the studs to support the back edge of the countertop and then added some vertical supports and large shelf brackets.

I wanted the shelves on the left side to be deeper than just the width of a 2x4 so I screwed 2x3s onto the 2x4s.

I drilled holes in a 48” inch aluminum ruler so that I can store it along the front edge of the countertop. This way I can use to measure things even when it is in its resting position.

The floor of the shed is about 10 inches off the ground so I used this hardware system to turn 2x8s into a ramp. I now have a nice easy way to provide access for my RYOBI Lawnmower.

It's always nice to have a little music in the shop and these wireless speakers from RYOBI are my favorite speaker system. The sound quality is great and they are super easy to set up and sync with a smart phone. These speakers use the same batteries as my power tools and are durable enough to withstand the elements outside.

I installed an Everbilt tool rack to store hand held yard tools.

No comments:

Post a Comment